Types of Lithium Ion Batteries

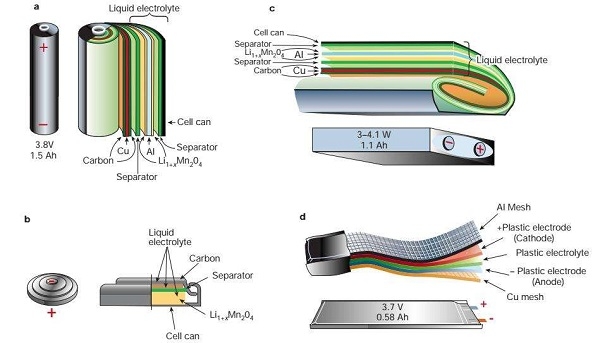

Lithium-ion batteries can be used in a variety of fields, so there are many types. According to the division of shape, there are mainly three types of lithium-ion batteries on the market, namely button type, cylindrical type and square type(C & D). Can meet the requirements of different uses.

The cylinder model is represented by 5 digits, the first two digits represent the diameter, and the last two digits represent the height. For example, the diameter of 18650 battery is 18mm and the height is 65mm, which is represented by 18*65. The first two digits are the thickness of the battery, the middle two digits are the width of the battery, and the last two digits are the length of the battery. For example, model 083448 is 8mm thick, 34mm wide, and 48mm long, and is represented by 8*34*48.

The size and weight of lithium-ion batteries are important indicators of lithium-ion batteries, which directly affect the performance of lithium-ion batteries. The electrochemical performance parameters of lithium-ion batteries mainly include the following aspects.

Rated voltage: The rated voltage of commercial lithium-ion batteries is usually 3.6v (currently, some lithium-ion batteries of 4.2v are also on the market, but the proportion is not large), the operating voltage range is 4.1--2.4v, and there is a lower limit termination The voltage is set to another value, such as 3.1v.

Rated capacity: refers to the capacity when constant discharge to terminal voltage 0.2c.

1C capacity: refers to the capacity from 1C constant discharge voltage to termination voltage. 1C capacity is generally less than the rated capacity. The smaller the difference, the better the current characteristics of the battery and the stronger the load capacity.

High and low temperature performance: The high temperature of lithium-ion battery can reach +55℃, and the low temperature can reach -20℃. In this ambient temperature range, the battery capacity can reach more than 70% of the rated capacity. Especially in high temperature environment, it generally has little effect on battery performance.

Charge capacity: The percentage of rated capacity obtained by discharging at 0.2c after the battery is fully charged for 28 days. The larger the value, the stronger the charging ability and the smaller the self-discharge. Under normal circumstances, the holding capacity of lithium-ion batteries is more than 85%.

Cycle life: As the lithium-ion battery is charged and discharged, the battery capacity is reduced to 70% of the rated capacity. The obtained charge-discharge time is called the cycle life. The cycle life of lithium-ion batteries is generally required to be more than 500 times.

According to the electrolyte form of lithium-ion batteries, lithium-ion batteries are divided into liquid lithium-ion batteries and solid-state (or dry) lithium-ion batteries. Solid lithium-ion batteries, commonly known as polymer lithium-ion batteries, are a new generation of batteries developed on the basis of liquid lithium-ion batteries, and have better safety performance than liquid lithium-ion batteries (commonly known as lithium-ion batteries).

Polymer lithium-ion batteries work on the same principle as liquid lithium-ion batteries. An important difference is that polymer electrolytes are different from liquid lithium-ion batteries. The important structure of a battery also includes three elements: the positive electrode, the negative electrode, and the electrolyte. The so-called polymer lithium ion battery refers to a battery system in which at least one or more of the three important structures are made of polymer materials. In the currently developed polymer lithium-ion battery systems, polymer materials are mainly used for the positive electrode or the electrolyte. Cathode materials include conductive polymers or inorganic compounds used in lithium-ion batteries, while electrolytes can be solid or colloidal polymers, or organic electrolytes. Lithium-ion batteries currently use liquid or gel electrolytes, so they require robust secondary packaging to preserve the battery's flammable active components, which adds weight and limits battery size flexibility. Lithium polymers do not contain excess electrolyte during the preparation process, so they are more stable, less likely to be dangerous due to overcharging, collisions and other damage to the battery, and less likely to be overused.